Design rules and principles: As the 3D printers are marvelous machines, they have certain limitations, these machines build or print objects by layers so their main enemy is gravity. We could appreciate this during the tests we made with the different shapes and settings for the machine.

Another really nice characteristic about 3d printing is that solid objects designed in 3d software are filled with a 3d mesh, this was new to me as I have never seen the process of the layering of the material, you can also change the settings of this interior mesh structure depending on what you want to accomplish. The software is really friendly and easy to use, quite straightforward and simple. In the case of the 3d scanner, it was amazing to see how these machines can scan and photograph objects with such a good resolution, software is also really easy to use and the machine is pretty intuitive in its design. Scanning other things different than objects was difficult due to the cable that is attached to the scanner.

We tried to scan my face and it had some errors due to speed of rotation and movement, however this scanner is amazing. Laser scanner was a little bit less dynamic as it needs a more controlled environment and it uses lasers to scan, it also takes a while to get all of the complexity of the object and it doesn’t rotate which makes it a bit difficult to get good scans out of it.

3D printing

As the assignment was to make a small object that could not be made substractively I decided to play with arrangements of basic geometry that can be designed very easily in 3D but that is very difficult to fabricate in one piece. I decided to play with the cube and the sphere, I used FreeCAD for the modeling. Found some good tutorials on how to make parts and play with shapes, the only thing I didn’t like about this platform is the inability to move freely and the orbiting options it has, coming from Archicad, Autocad and Sketchup this way of making shapes seemed very slow, however I assume there must be a better and faster way to do this.

I inscribed the sphere in the cube and decided not to cut it anywhere so that an apparent cube in shape could host another hollow shape, its negative. You are not able to see it bout the actual negative of the sphere is there.

As the printer started the job I decided to place an object inside the negative of the sphere in order to get some sense of the hollowness of the cube. I believe that by listening to this object inside of the cube people will be able to guess the negative shape inside the cube. It could be an interesting game to play.

3D scanning

I tried to scan with the new scanner but it wasn’t working so I decided to do it with the laser scanner, first I tried to scan a set of keys but it was impossible, the shapes were too intricate and it didn’t scan much, after a closer look to the model I realized I hadn’t put the keys in focus so the scanner was failing; this is very importanto for every scan so as they work with cameras and they adjust their focus and aperture.

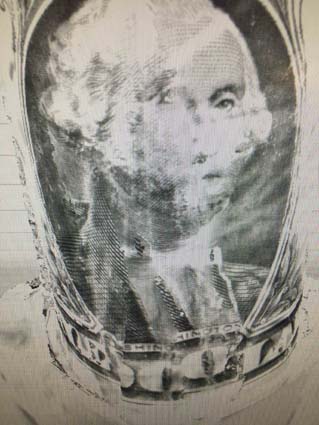

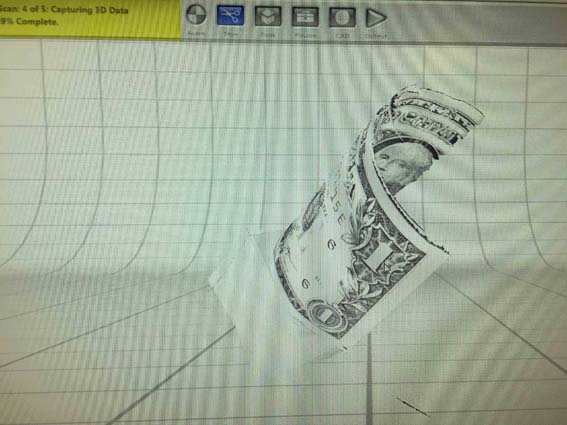

I then decided to scan a 1-dollar bill and change the settings to MACRO, I arranged my object so that it was focused and the model came out in a very defined way. It was turning on really well, however, the bill was rolled and the scanner wasn’t able to grasp all of the shape of the bill.

Then I tried to fill it but it made a huge mess. I played with some other parameters and finally got a fairly decent model out of it.

It was a great experience to work with both processes, I believe they are very useful and for sure will incorporate them in my future work.